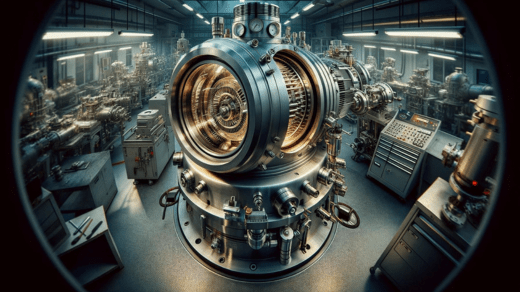

In the realm of vacuum technology, side channel vacuum pumps stand out as innovative solutions offering unparalleled efficiency and performance. These pumps, often referred to as dry vacuum pumps, are at the forefront of industrial applications, powering various processes with precision and reliability.

Introduction to Side Channel Vacuum Pumps

At the heart of vacuum systems, side channel vacuum pumps play a pivotal role. Unlike traditional rotary vane vacuum pumps or oil Vacuum Pumps , side channel pumps operate on a unique principle, utilizing the kinetic energy of rotating impellers to create vacuum.

The Mechanics Behind Side Channel Vacuum Pumps

A distinguishing feature of side channel vacuum pumps is their ability to generate vacuum through the centrifugal force created by rotating impellers. As gas molecules enter the side channel, they are accelerated and forced towards the exhaust, effectively creating vacuum pressure.

Advantages of Side Channel Vacuum Pumps

One of the key advantages of side channel vacuum pumps is their dry operation, eliminating the need for lubricants like oil. This not only reduces maintenance but also prevents contamination in sensitive applications.

Applications of Side Channel Vacuum Pumps

From packaging and food processing to medical equipment and automotive industries, side channel vacuum pumps find widespread use. Their ability to handle both clean and slightly contaminated gases makes them versatile across various sectors.

Exploring Rotary Vane Vacuum Pumps

While side channel vacuum pumps offer unique benefits, traditional rotary Vane Vacuum Pumps remain prevalent in certain applications. These pumps operate by trapping gas molecules in rotating vanes, creating vacuum through displacement.

Comparing Side Channel Vacuum Pumps with Rotary Vane Vacuum Pumps

In terms of efficiency and reliability, side channel vacuum pumps often outperform rotary vane vacuum pumps. Their dry operation, higher vacuum levels, and lower maintenance requirements make them a preferred choice in many scenarios.

Understanding the Role of Oil Vacuum Pumps

In contrast to dry pumps like side channel vacuum pumps, oil vacuum pumps rely on lubricants for operation. While effective in certain environments, they pose challenges in industries where oil contamination is a concern.

The Evolution of Vacuum Technology: The Rise of Side Channel Vacuum Pumps

As industries demand cleaner, more efficient vacuum solutions, the demand for side channel vacuum pumps continues to grow. Companies like Becker-International are at the forefront of this evolution, offering cutting-edge technologies to meet diverse needs.

The Impact of Side Channel Blowers

In addition to side channel vacuum pumps, side channel blowers play a crucial role in various applications. These devices, often integrated into vacuum systems, provide the necessary airflow for optimal performance.

Choosing the Right Vacuum Solution

When selecting a vacuum pump, it’s essential to consider factors such as flow rate, vacuum level, and operating environment. Becker-International offers a range of solutions, including side channel vacuum pumps, tailored to specific requirements.

Maintaining Side Channel Vacuum Pumps

While side channel vacuum pumps are known for their reliability, regular maintenance is crucial to ensure optimal performance. Simple tasks such as cleaning filters and inspecting seals can prolong the lifespan of these pumps.

Future Trends in Vacuum Technology

Looking ahead, the future of vacuum technology lies in innovation and sustainability. As industries strive for greater efficiency and eco-friendliness, side channel vacuum pumps are expected to play an increasingly integral role.

In conclusion, side channel vacuum pumps represent a paradigm shift in vacuum technology, offering unmatched efficiency, reliability, and versatility. As industries continue to evolve, companies like Becker-International remain committed to delivering cutting-edge solutions that drive progress and innovation.

+ There are no comments

Add yours